Ming Min from the concave temple

Qubit Report | Public Account QbitAI

I don’t know if you have seen a video similar to “Glass Marble Making”.

In the video, the worker master needs to heat the glass material at a high temperature and then quickly shape it in a fluid state.

Although we are across the screen, we will also sweat for the operator. After all, the bright brightness makes it very hot to look at!

However, a recent study by Science shows that Now it is possible to inject glass under low temperature conditions!

Frederik Kotz and Bastian E. Rapp of the University of Freiburg in Germany proposed a high-throughput injection molding process using silica nanocomposites.

They combined the low-temperature injection molding process (IM) with water-based degreasing and low-temperature sintering processes to develop a new glass processing technology compatible with injection molding technology, which can quickly mass produce high-precision glass products with smooth surfaces.

Processing glass is not that simple

This technological breakthrough can be said to solve the core difficulties of the current glass processing industry.

first of all, High temperature melting, castingIt has always been a problem that plagued the glass processing industry.

The high temperature requirement above 1500℃, on the one hand, causes huge energy consumption during processing (It is estimated that every ton of glass processing needs to consume 5-6 megajoules of energy); On the other hand, to a certain extent, it limits the capacity and efficiency of glass industrial processing.

Secondly, the processing of glass micro-morphology mostly uses hydrofluoric acid, laser etching, etc. The preparation process is dangerous, difficult to operate, and pollutes the environment. The shape and output that can be processed will also be limited.

How to achieve?

However, Markus Mader and others used a low-temperature injection molding process (IM) combined with a water-based degreasing and low-temperature sintering process, which just solved the above problems.

Technical core—— Injection molding process (IM)It is a kind of rapid processing technology suitable for industrialized production. It finally produces a semi-finished product with a certain shape by pressurizing, injecting, cooling, and detaching molten raw materials.

Previously, this technology was mostly used in the processing and production of polymers. This time researchers have applied it to glass processing in a breakthrough.

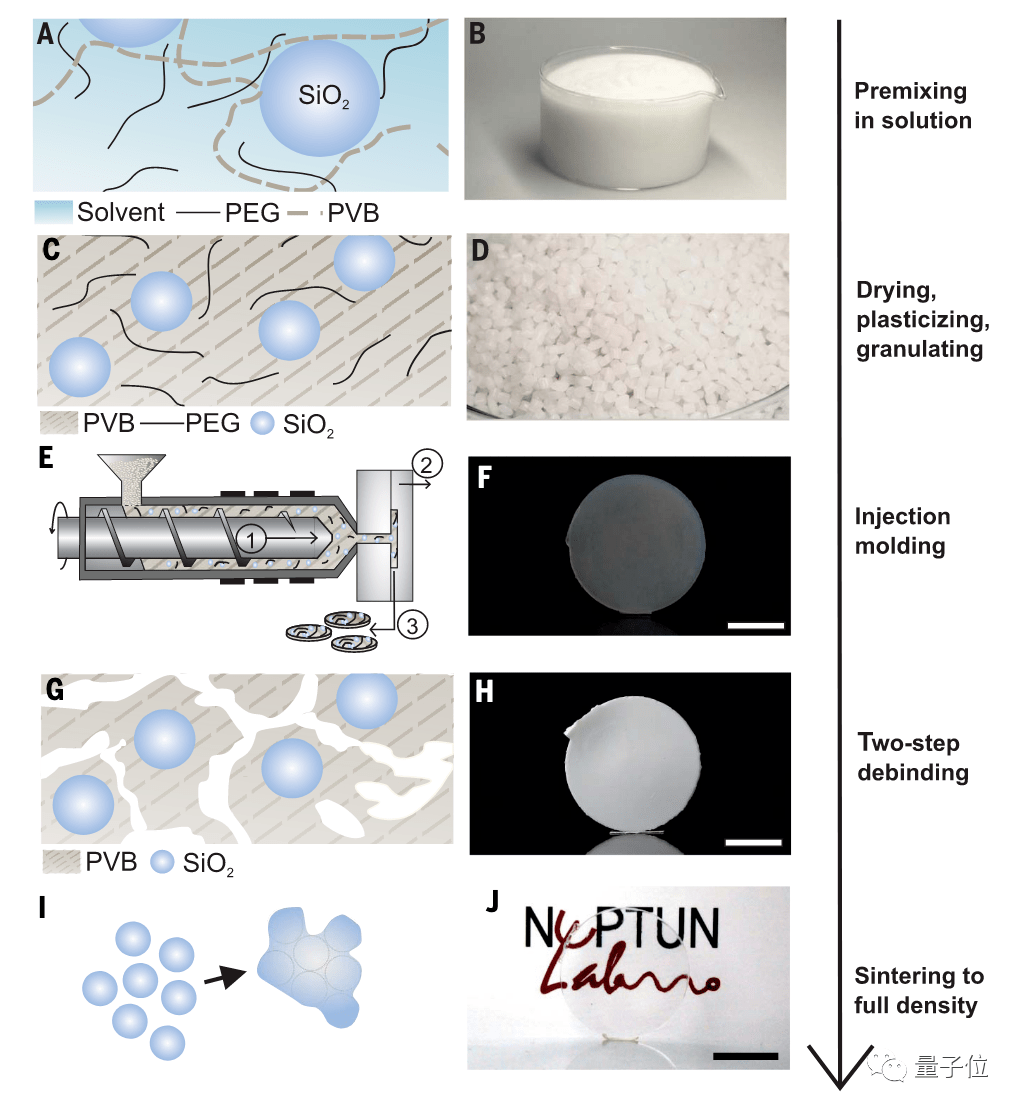

First, the researchers pre-mixed silica nanopowder, vinyl butyral (PVB) solution, and vinyl butyral (PEG) solution, and evaporated to obtain a thermoplastic silica composite.

Then use a twin-screw extruder to plasticize and extrude the obtained material to obtain granular raw materials;

Followed by 130°C, Injection molding at a specific pressure of 700 ~ 1000 bar, obtained Green bodysection;

Soak the green body in water at 40°C first to remove the PEG from the material, and then use high temperature to remove the remaining binder;

Finally, high-quality transparent fused silica glass is obtained by sintering in a vacuum environment at 1300°C.

Due to the optimized two-step degreasing process, the injection molded green parts (less than 2 mm in size) are converted to transparent fused silica, and only a total of 24 hours.

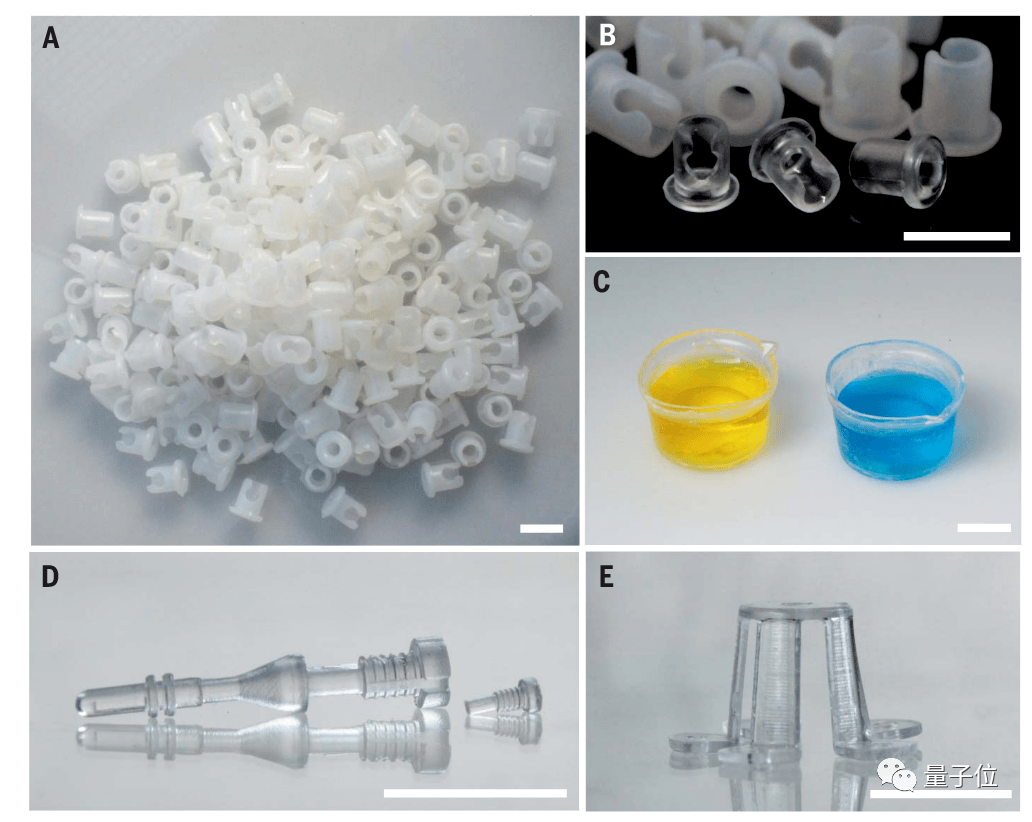

In addition, the researchers further used the technology to perform high-throughput manufacturing on a commercial injection molding machine (Babyplast Christmann).

It was found that even if the silica nanocomposite is fully automated injection molding with a cycle time as low as 20 seconds, it is possible to produce complex-shaped fused silica parts at the industrial production level.

More than 200 parts were produced in 18 minutes, which means One glass component can be produced every 5 seconds!

Not only that, the energy consumption of the whole process Less than 60% of traditional processing technology; And because the degreasing process is not carried out in a high temperature environment, the adhesive used in the process can still recycle and re-use.

△Frederik Kotz

Researcher Frederik Kotz said: “This method can finally get high-purity silica glass of any shape.” And said that these glass parts will eventually have Commercial telecommunications equipment and chemical reactorsThe required optical and chemical properties.

△André Studart

André Studart, a materials scientist at ETH Zurich, said that this method can lead to more new ideas.

However, he proposed that this new method of mass production of glass components still faces a bottleneck: The PEG removal process takes several days, To ensure that the glass parts will not crack.

“If this process is accelerated, glass injection molding will become as popular as plastic!”

Reference link

[1]https://science.sciencemag.org/content/372/6538/182

[2]https://www.sciencemag.org/news/2021/04/glass-molded-plastic-could-usher-new-era-complex-shapes

— Finish—

This article is the original content of the NetEase News•NetEase Featured Content Incentive Program signed account[qubit]. Unauthorized reprinting of the account is prohibited.

Join the AI community and expand your network in the AI industry

Qubit “AI Community” is recruiting!Welcome AI practitioners and friends who are concerned about the AI industry to scan the QR code to join, and 50000+nameFriends pay attention to artificial intelligence together Industry Development & Technology Progress:

Qubit QbitAI · Toutiao Signing Author

վ’ᴗ’ ի Tracking new trends in AI technology and products

One-click three consecutive “Share”, “Like” and “Looking at”

The frontiers of science and technology are seeing each other~

You must log in to post a comment.